Smith Optics elevates the outdoor experience through innovation

OVERVIEW

Smith Optics is focused on building better goggles, helmets, and eyewear to deliver a better outdoor experience. The brand has ventured into 3D printing and technology partnerships to develop Imprint, a personalized approach to gear that offers significant performance enhancements and a customizable buying process. Its first product, I/O MAG Imprint 3D, earned recognition as a Time Magazine Best Invention of the Year. Smith now plans to extend the Imprint concept to more products.

SCOPE

Custom App Development, Experience Design, Cloud Native Development, Mobile Engineering, Quality Engineering, Prototyping

TECHNOLOGY

iOS, Swift, AWS Amplify, Salesforce Commerce Cloud, Amazon S3, AWS Lambda, Structure SDK, Microsoft Visual Studio App Center

Taking the lead on goggle comfort and fit

Fit is the biggest challenge in sports equipment. Without exception. Creating gear and apparel that is not only beautiful and functional but truly comfortable has always been the goal. With ski goggles in particular, the challenge has to do with faces. Sizes, shapes, and individual features can all dramatically affect a quality fit. When obstacles—or a killer view—are ahead of you, your vision should be as impeccable as your turns.

Legendary ski goggle manufacturer Smith Optics decided to tackle this monumental challenge and set their sights on creating what it hoped to be the future of the industry. A perfect fitting goggle for all-day comfort, free from light leaks, air gaps, and pressure points, with a minimum of obstructive foam, and an unparalleled field of vision for all face shapes.

At the same time, Smith wanted the purchasing process to be quick and easy enough that a rider could place an order while sitting on the couch watching shred videos. And if there was opportunity to offer customized and personalized gear, all the better.

Smith had the vision and its teammates—Slalom Build, AWS, and Structure—supplied the know-how. Together, we climbed into the gondola for the run of our lives, which landed Smith on the pages of Time Magazine with recognition for a best invention of the year. Here’s what we accomplished.

The rewards of adventurousness

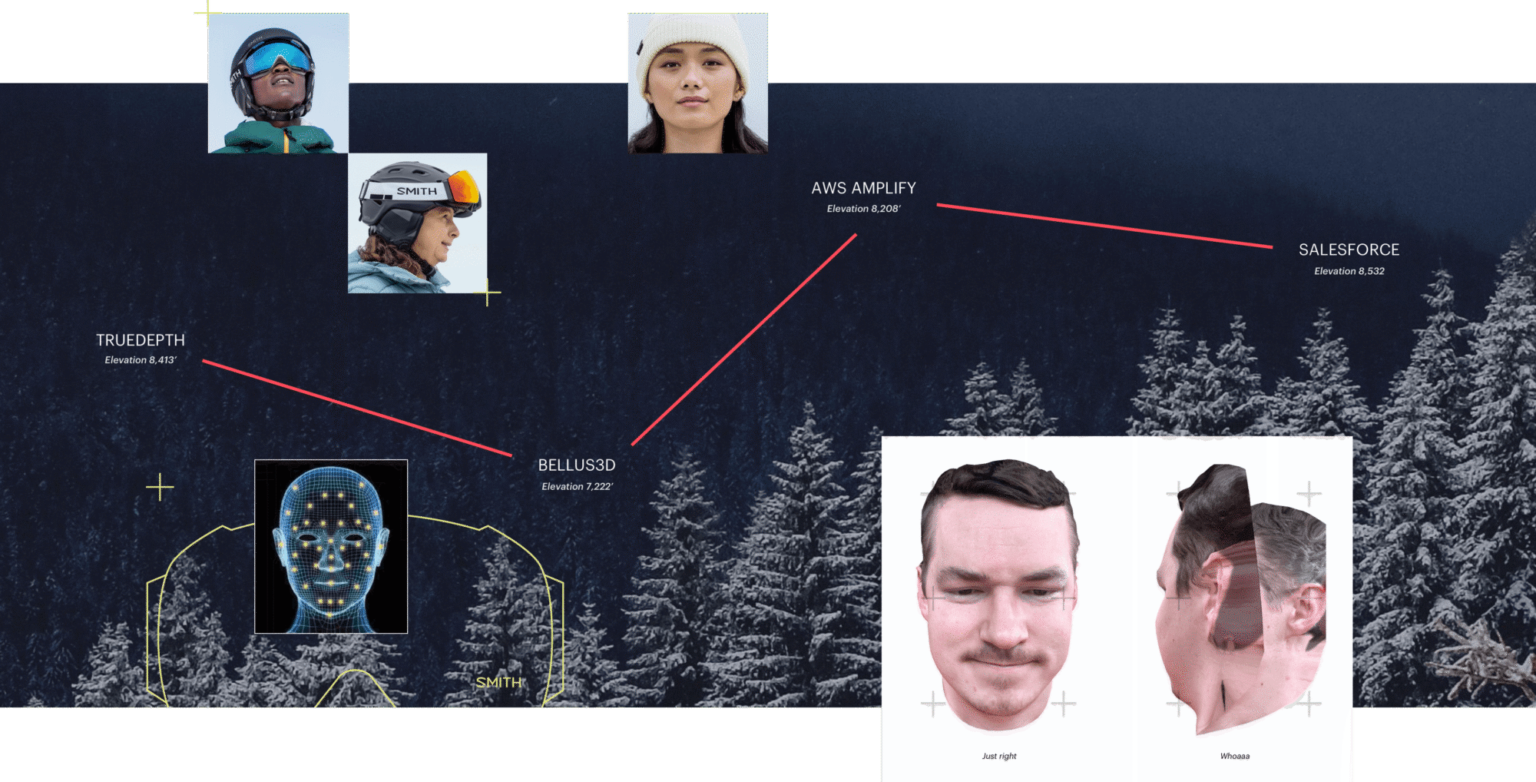

First, there’s the product itself. An immersive app using Apple’s latest TrueDepth camera and Lidar sensors captures the detail needed to create an extremely accurate face scan. The goggles are manufactured to fit, incorporating a 3D-printed face flange and delivered within 14 business days.

Second, Smith has a new, blazing quick go-to-market process. The traditional development cycle was cut from 18–24 months to 4–6 months, so new offerings can hit the shelves up to 80% faster. That means more opportunity for iterative design and market testing, and a highly responsive manufacturing process.

Third, Smith has received great attention for these innovative goggles, from raving customer reviews to historic site traffic to positive earned media, including recognition from Time and the Outdoor Retailer Innovation Award.

This initiative means more than just an exceptional experience for riders; it’s transformational for Smith. Connecting with Slalom Build and taking advantage of new technologies is helping the brand stay ahead of the curve. The Imprint project represents the company’s future and continues its commitment to riders to keep making great gear that is inclusive for all and helps create the best outdoor experience possible.

From idea to delivery

Behind all that magic was a deep collaboration with Amazon Web Services and its Amplify offering. AWS Amplify is a set of purpose-built tools and services that helped us spin up and run multiple development environments with ease, meaning simultaneous development, testing, and production throughout the project. Amplify allowed the team to quickly utilize AWS services like Cognito, S3, Lambda, shaving weeks off the process. We also integrated with Salesforce Commerce Cloud for secure authentication, customer validation, and order verification.

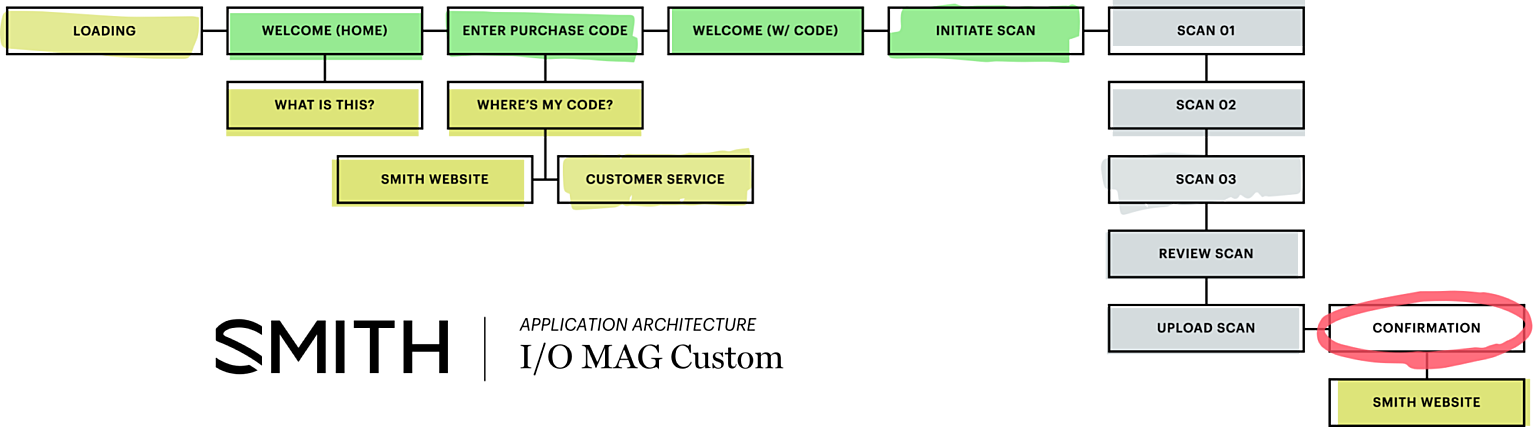

From discovery to idea refinement to app architecture to prototyping—all the way through website, manufacturing, and shipping integration—Smith, Slalom Build, and the numerous technology teams needed to be in sync throughout to deliver before the first flakes fluttered toward the ground.

The perfect app for the perfect fit

How does someone get from tapping the app to hitting the slopes?

Here’s how the magic happens:

First, the customer visits SmithOptics.com where they pick strap and lens colors.

Next, a customer downloads the app.

Then they use the front-facing camera on their iPhone to take a detailed 3D face scan.

Every measurement, each curve and contour that make up a person’s face are then used to create an individual model and custom CAD file, which is sent to Smith’s production facility in Utah.

From there, the frame is 3D printed; the foam, lenses, and straps are added; and the whole thing shipped off.

The user’s initials are even etched into the frame for easy identification and ultimate personalization.

In short: tap, scan, print, ship, shred. All in two weeks or less.

Introducing the Smith I/O Mag Imprint 3D. The most perfectly individual, absolutely customized ski goggles.

The next run

Since initial app delivery, the relationship has continued to evolve. We’re making continuous fidelity and experience refinements to respond to ever-changing customer needs, and the technologies available to meet them.

Slalom Build is super proud to have worked with Smith and the other technology teams on this truly transformative moment for Smith, a real testament to our shared belief in the power of technology to breathe life into an inspiring vision.

Next up